Machine Vision Media Interview -- An Interview with Mrs. Xi Yunxia, Marketing Director of Intelligent Sensing Department of ASM

X: Xi Yunxia M: Machine Vision

Interrespondent: Dr. Yunxia Xi is currently the Marketing Director of IntelliSense Division at ASM Semiconductor, responsible for the market development of IntelliSense products in Greater China, including the expansion in the field of autonomous driving. Prior to joining ASM, she worked at Infineon, Freescale, NXP and many other semiconductor companies, where she was involved in chip architecture design, system application development and market development. He has rich professional experience and project achievements in the fields of embedded chip architecture design, industrial and automotive system application solutions, intelligent sensing solutions, etc. Dr. Xi holds a Ph.D. degree from the National University of Singapore.

M: In February this year, ASM was selected as one of the world's most ethical companies for the sixth time in a row in 2021, which is a rare honor in the machine vision industry. Could you please tell me the importance of high business ethics for a company's development?

X: Thank you for your attention to this topic. Business ethics are crucial to the development of a company. There are many well-known enterprises, but few can claim that they have business ethics standards, and it is not easy to obtain this honor sustainably. For the sixth year in a row, ASM Semiconductor has been recognised as one of Ethisphere's World's Most Ethical Companies. In addition, the evaluation of a company is not only from the profit, but also from the consideration of customers, partners, suppliers, environment, society, safety, fairness, social justice, etc., which is the connotation of this business ethics standard. This award enables ASM Semiconductor to gain higher trust from the industry and partners, which is an important foundation for the sustainable development of a company. ASM Semiconductor is rooted in environmentally sustainable operations and business ethics. A member of Barron's 100 Most Sustainable Companies list for the past four years, ASM recently moved up to No. 10, making it the top semiconductor company on the list. In 2020, ASM also received the Platinum Award, the highest award from EcoVadis, a leading platform for environmental, social and ethical performance ratings of the global supply chain. ASM ranked in the top 1% of companies evaluated and was named the most sustainable company in the semiconductor industry by World Finance Magazine.

M: In recent years, ASM has focused on automotive and industrial development. Will this Vision China (Shanghai) show also bring relevant products and technologies?

X: Automotive and industry are indeed the main development direction of ASM Semiconductor. Vision China is a grand event of industrial Vision, so this time we mainly show products related to industrial applications.

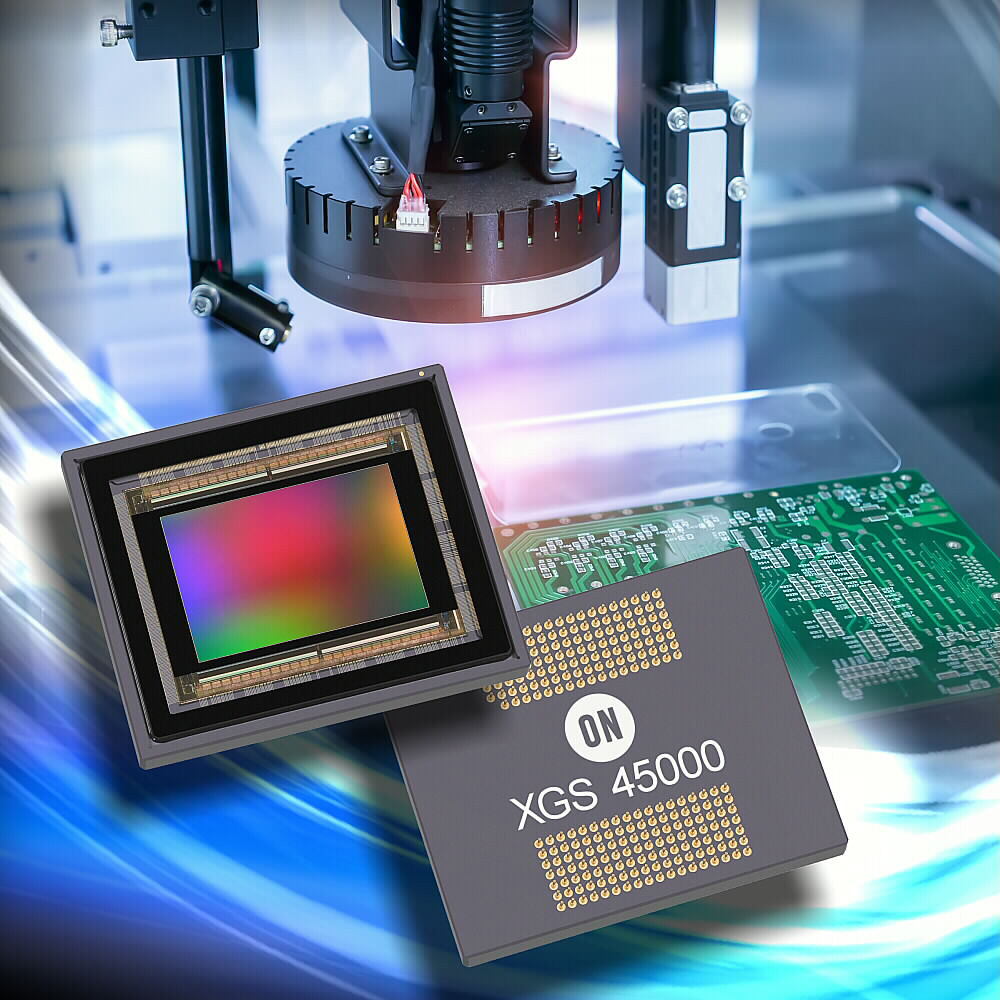

This time we show the industrial XGS series, the economical GS series, RS series products. XGS is our latest generation of industrial-grade GS image sensor, which uses the latest 3.2um Pixel technology to provide excellent image quality, low noise, good consistency, high frame rate, low power consumption, wide operating temperature, and excellent cost performance advantages for a variety of industrial applications. It is a serialized X-class platform of family products, from 2M to 45MP. It can be compatible with a total of 11 resolutions with two sets of hardware circuit boards, among which 2m-16m can easily fit into a 29*29 camera platform, 20m-45m can be pin-to-pin. The customer designs a hardware platform to select the corresponding resolution sensor according to the specific application requirements. Camera manufacturers can leverage existing inventory of parts and speed up time to market for new camera designs. This generation of products will overturn the current market competition pattern, providing users with a very attractive choice.

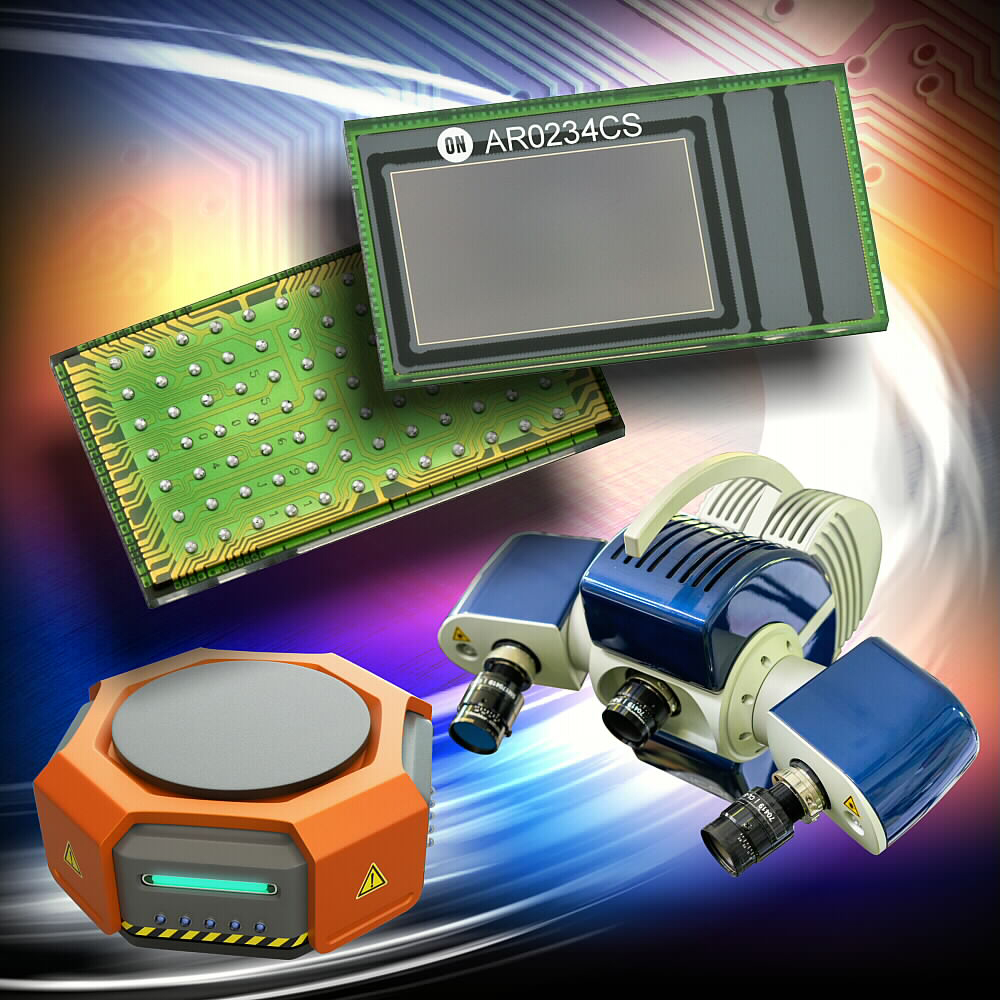

R0234 is an economical GS chip from ASM. Its resolution of 2M and 120 frame rate are suitable for most traditional industrial detection. Its resolution, rate and optical size can be used for industrial code scanning, binocular depth measurement, etc. We also use ASM's own SoC AP1302 to do the corresponding solution. Help customers speed up development. AR0521 is a BSI RS image sensor. It can capture 5 megapixel images at 60 FPS. We have also made a near-infrared enhanced version of the AR0521. The 5M resolution is suitable for a wide range of applications, including security, industry, and edge AI. We use the thermal meter reference design of AR0521 in this exhibition. AR0822 is the latest generation of ASM stack-based, backlighting technology 1/2 inch image sensor, pixel size 2.0um, active pixel array of 3840x2160 standard 4K, supporting linear and high dynamic modes. It supports 3-exposure HDR synthesis mode, but also supports single exposure, high dynamic output mode, very suitable for the high-end security market.

The RSL10 intelligent camera platform embodies the next evolutionary development of the Internet of Things: the need for ultra-automation and low power consumption. The platform uses artificial intelligence (AI) to achieve event-triggered imaging. It brings together a number of ASM innovations, including the RSL10 SIP, which provides ultra-low-power Bluetooth low-power technology, and the low-power ARX3A0 MONO 65° DFOV IAS module, coupled with advanced motion and environmental sensors as well as power and battery management to bring automatic image recognition to the Internet of Things.

M: Which of these products are the main products of ASM Semiconductor this year? Compared to the same product, what is the highlight of it?

X: The main product of ASM this year is the XGS series, which is our latest generation of industrial-grade GS image sensor. With the latest 3.2um Pixel technology, the image quality is good, noise is low, consistency is good, high frame rate, low power consumption, wide operating temperature, and extremely cost-effective, can be used in a variety of industrial applications. It is a serialized X-class platform of family products, from 2M to 45MP. It can be compatible with a total of 11 resolutions with two sets of hardware circuit boards, among which 2m-16m can easily fit into a 29*29 camera platform, 20m-45m can be pin-to-pin. The customer designs a hardware platform to select the corresponding resolution sensor according to the specific application requirements. Camera manufacturers can leverage existing inventory of parts and speed up time to market for new camera designs. This generation of products will overturn the current market competition pattern, providing users with a very attractive choice.

The high resolution XGS3000/32000/45000 platform is mainly used for PCBA inspection of SMT, flat panel/wafer/photovoltaic inspection, and 8K video broadcast image. For example, the live broadcast of the Tokyo Olympics will be used.

ASM Semiconductor provides integrated system hardware solutions and works with ecosystem partners, especially FPGA and SoC suppliers, to provide one-stop solutions. The X-Cube meets the machine vision industry standard of 29 X 20 mm2, supports 16 /12 /5 megapixels, and will help customers integrate XGS solutions into their cameras and speed up time to market for applications such as machine vision and intelligent transportation systems.

We have a High Speed Nut Counting System on display to demonstrate that the cost-effective XGS 12000 can capture sharp, high-resolution images up to 90 frames per second (FPS).

M: Cross-boundary cooperation and technology integration are the trend and opportunities of the development of the entire machine vision industry. With the current innovative technologies, such as edge computing, artificial intelligence, deep learning, embedded vision, 5G+, etc., which innovative technologies will your company focus on in the future?

X: ASM will cooperate in the above aspects, because edge computing, artificial intelligence, deep learning, embedded vision and 5G+ are all industry trends for future development. Today, AI is used in more than 60 percent of computer vision applications, and the growth of AI in manufacturing applications has exceeded 50 percent CAGR. Artificial intelligence is the new tool we need to manage the ever-growing data sets from industrial imaging to achieve Industry 4.0.

AI decisions for imaging have migrated from the cloud to the edge - to computer systems that are adjacent to or incorporated into the imaging system itself. For example, by keeping the training of artificial intelligence in the GPU or the cloud, the stack process can be used to integrate decision making or even some preprocessing related to it into the image sensor itself. The low level or small computational force convolutional neural network layer for image recognition is integrated on the sensor. These AI functions will be integrated into the image sensor.

5G networks provide convenient, high-speed, high-bandwidth, low-latency, high-reliability data transmission channels, which makes sense for machine vision. Usually, the amount of data of the image sensor is relatively large. For example, we have a 12M image sensor, and the amount of data of a frame is 144MB (12bit/pixel). If there is no high-speed, high reliability network, such data volume can only be processed directly at the terminal, which limits the information processing and interaction ability. With the support of 5G network, data can be sent to the cloud, and more complex operations can be realized and the results can be returned in real time. For example, during the anti-epidemic period, the combination of 5G and vision has made us all "cloud supervisors" for a time.

We will consider the needs of these new technologies in perceptual products, and make better improvements in interfaces, computing, dimensions, power consumption, process and so on.

M: Ansemite semiconductor sensing products are widely used in a wide range of applications. What is the market layout of Ansemite in China?

X: ASM has a wide range of Intelisense products, which are used in automotive, industrial and consumer applications, all of which have a rapid growth trend in China.

In terms of cars, our global share of ADAS and L2+ autonomous driving is as high as 80%. China's auto market is also moving towards advanced autonomous driving. L2 class cars begin to be equipped with more than 10 cameras. We will focus on automatic driving, including in-cabin monitoring. Our international experience can help us to implement local technologies and realize higher degree of intelligent vehicles.

On the industrial side, we have a plan and layout for the fast-growing markets we mentioned earlier. Using our ultra-high resolution and high-speed image sensors for applications such as screen inspection, photovoltaic, semiconductor inspection, our economical global shutter image sensor layout in a variety of industrial scanning, logistics, artificial intelligence and other fields. In terms of 3D applications, we can control various image sensors, as well as DTOF solutions based on SIPM, SPAD Array single point, linear array and planar array.

On the consumer side, we have economical image sensors with HDR, etc., and will continue to make strength in AI, especially in various face recognition applications, security, IoT and other markets.