Made in China 2025 is the first ten-year action program for China to implement the strategy of manufacturing power. The goal is to realize the transformation from manufacturing power to manufacturing power, among which intelligent manufacturing is the main direction. With the development of related technologies, manufacturing industry in China has gradually penetrated into high-end and complex fields such as assembly and testing.

Intelligent manufacturing is a new production mode

It will adopt a variety of advanced technologies

For example, robots, artificial intelligence, Internet of things, big data, etc

Further efficient, energy-saving and flexible plants

among

Machine vision is a key technology to advanced manufacturing

Industrial vision can be used to detect the surface information of products, non-contact measurement of product appearance size, to judge the coordinates of object position, to identify and judge the color and shape of objects. From the perspective of application technology, industrial vision can cooperate with robots to realize sorting, assembly, printing and other processes, as well as high-performance and precision components detection and measurement. The latter requires higher precision, but it is also difficult for human eyes to achieve and demand is also greater. Industrial vision is equivalent to giving a pair of eyes to the production process, which makes manufacturing intelligent, and opens up a new "Horizon" of intelligent manufacturing.

So, what machine vision technologies make manufacturing more "intelligent"?

Follow the editor and see

The perception technology of machine vision

The machine vision technology has high self-adaptive and intelligent performance, and the imaging technology, image automatic acquisition technology, image automatic processing technology, image registration and joint control with intelligent equipment have realized outstanding perception ability. Specifically, the perception technology of machine vision can be effectively applied in the fields of product detection, precision measurement and control and automatic production line in intelligent manufacturing. Machine vision technology makes industrial robot have stronger perception ability. The eye function makes it not need to have offline programming mechanism in advance, but also can get rid of the preset motion track. Through the guidance of perception ability, it can automatically identify and process scene information, complete the disposal of grab specified objects, and make the production process more intelligent and flexible.

Dynamic monitoring and feedback technology of machine vision

In traditional production and manufacturing, although the application of automatic production line greatly improves the production efficiency, in practice, due to the complexity of the system, once the failure may affect the whole production line, resulting in the loss of product quality, enterprises will also face huge economic losses. The dynamic monitoring and feedback technology of machine vision technology solves the corresponding problems well. In visual technology, dynamic monitoring and feedback technology can monitor and feedback the production line in real time, and control the product quality errors in the production and manufacturing process. Through the application of fault tolerance, the error rate of product quality is greatly reduced, and the production defect rate can be avoided and the production defect rate can be avoided. At the same time, the industrial monitoring visual technology can realize real-time communication and feedback through closed-loop adaptive control of visual monitoring and image lossless compression. According to the test results, the position adjustment, quality screening, data statistics and so on can be automatically completed, which helps the control and overall deployment of intelligent production and manufacturing links. From the current application situation, the technology is still in the initial stage of R & D and application.

Overview of the application of machine vision technology in intelligent manufacturing

The application of machine vision technology in intelligent manufacturing involves many fields, and with the development of the research of the technology. From the current application, it involves many different fields, including medical devices, electronic manufacturing, automobile manufacturing, etc.

First, the application of machine vision technology in medical equipment industry can be used for defect detection in medical equipment industry. It can automatically screen and eliminate the quality of medical products. Combined with the automatic equipment, the appearance defects of injection needle are detected online, and the unqualified products can be eliminated automatically. Secondly, the application of machine vision technology in electronic manufacturing, such as chip must be welded with very thin welding line, and the fine aluminum or gold wire should be placed on very small cushion surface with absolute accuracy. By machine vision technology, the position of welding and processing can be well realized, and the production and processing work of high-precision point can be well completed. In addition, in the field of automobile manufacturing, machine vision system is widely used in the field of automobile manufacturing condition monitoring, finished product inspection and quality control, and the practical application effect is more and more obvious.

With the development of "machine changing" in manufacturing industry, machine vision, which is necessary for the intelligent process of equipment, will also develop rapidly. Machine vision technology is a tool that can help factories reduce pollution and get high efficiency at lower cost. It can be predicted that with the maturity and development of machine vision technology, it will be widely used in modern and future manufacturing enterprises.

The implementation plan of intelligent application of machine vision brand at home and abroad

Huarui technology -- domestic coder helps industry reduce cost and increase efficiency

Huarui technology has expanded a number of series of code reading products this year, such as 7000 series 20million pixel code readers with large vision and large depth of field, 12 million pixel code reader of packaging box reading experts, etc. users can choose the best performance and cost-effective scheme according to their actual needs to achieve cost reduction and efficiency.

Source: Huarui technology public official account

For the application of 3C industry, Huarui technology has released a new small-scale code reader, which is only 50x50x28mm in size, which is suitable for reading code scenes in narrow and small space. At the same time, the height of small body is integrated with lens and red and white light source, which can meet the requirements of flexible light supplement in different scenes. The product can support reading more than 2mm paper code and DPM code, and polarization model can be provided for selection in the face of reflective workpiece.

Source: Huarui technology public official account

Lommai LMI -- gocator ® On line detection of defects in fiber cement board by multi-sensor system

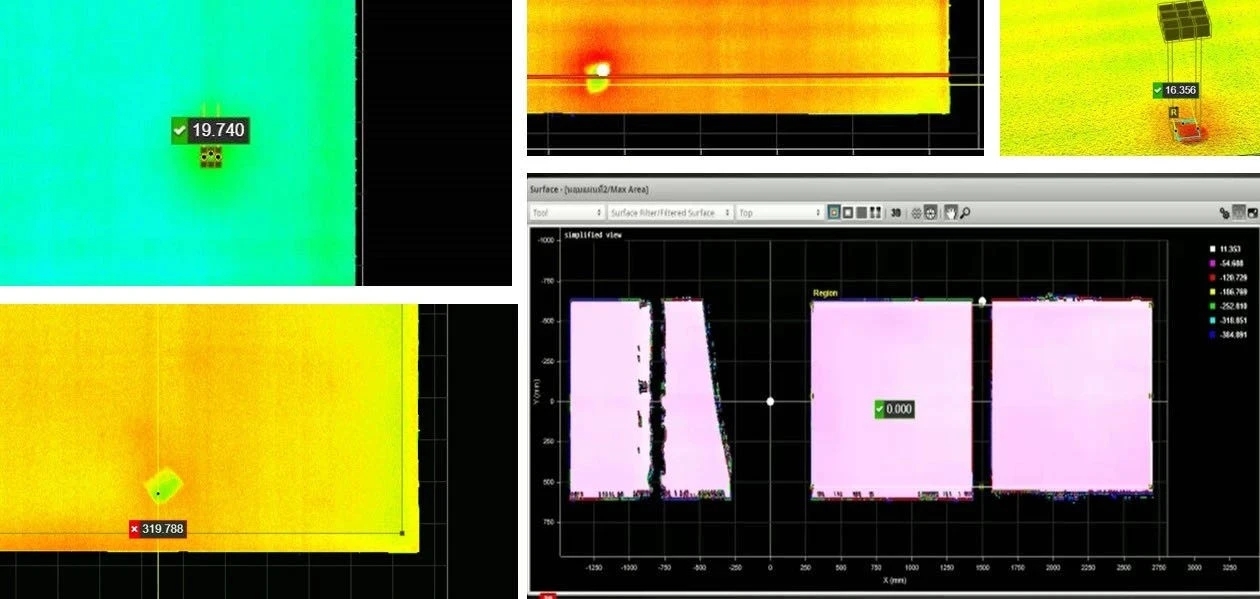

A large cement manufacturer in Thailand chose to use the ocator of LMI to improve production efficiency and product quality ® The multi-sensor system can detect the defects of fiber cement board online, instead of the traditional method of manual inspection, not only realize intelligent production line, but also effectively improve the overall production efficiency and save the total cost of the company.

Solution: in 7 production lines, each production line has applied 12 sets of ocator 3D line laser contour sensor network. Each sensor networking system has 4 large field gocator 2380 sensors installed at the top of the production line and 8 2180 sensors at the bottom.

Source: Le mu LMI official account

The advantages of the gocator:

Scanning the target with large field of view through the calibration and splicing function of multi-sensor network without scanning dead angle

Obtain high precision 3D scan data and accurate measurement data

rich measuring tools built in without the need to develop other tools

Integrated design integrates scanning, measurement and control, maintaining the lowest system without additional controllers or industrial PCs

Cost

Pre calibration has been carried out at the factory, and can be scanned and measured when it is unpacked

Easy to integrate with existing plant systems

Gocator scan and fiber cement board surface defects

Source: Le mu LMI official account

Shenzhen exhibition empowers the whole industrial chain of machine vision and intelligent manufacturing

Every year, there are many machine vision brands participating in visionchina Shanghai or Shenzhen exhibitions, especially those applied in the field of intelligent manufacturing, which bring new products and important products to the public, including Daheng, Lingyun, Haikang robot, Langde, Huarui, Keanes, vieworks, Sike, Zhixiang, SanRui automation, wadep, lommai LMI, long track, etc. On November 3-5, visionchina (Shenzhen) will visit Shenzhen International Exhibition (Bao'an New Museum), jointly hold the Munich South China Electronic Exhibition, Munich South China electronic production equipment exhibition, South China advanced laser and processing application technology exhibition, and the four exhibitions will be linked to introduce vision plus X concept, integrate laser, electronics, intelligent manufacturing and other fields, and show the machine vision in artificial intelligence The innovative application and customized solutions under the wave of "5g+", "+ai" are built to build a professional trading exchange platform integrating the market of machine vision terminals such as electronics, intelligent manufacturing, automation and robot, laser processing.

Shenzhen exhibition will focus on 5g and new infrastructure, and will present the industrial AI, deep learning, visual detection, 3D vision, machine vision core components and accessories, automation and robot, intelligent warehousing logistics, intelligent solution for electronic manufacturing, semiconductor and system design technology, exciting light processing ten modules and smart factory features, It is the power of the whole industrial chain of machine vision and intelligent manufacturing.