Q: What products, technologies and solutions will your company bring to VisionChina2022 (Shenzhen)? What are the highlights? What changes will this have on your own competitiveness?

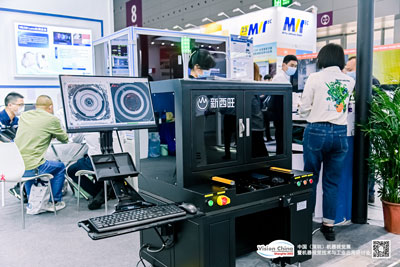

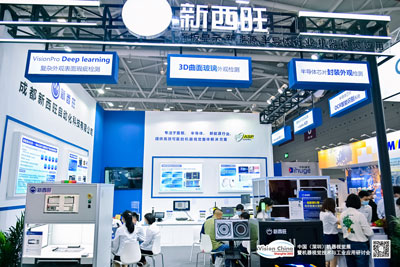

A: In this VisionChina2022 (Shenzhen) exhibition, the products we bring are high-precision alignment system, AOI inspection system, data information system (including BC system, automatic code reading and accounting system, VCR system) and testing equipment for various industrial manufacturing sites (assembly accuracy, point decoding, chip testing, automotive connecting rod testing, etc.). All these products are the final product forms presented by the fusion of NWS's own technology and the advanced technology of the industry. For example, the high-precision alignment system is a universal alignment system developed by Xinxiwang with its own intellectual property rights based on its own high-precision alignment algorithm, high-precision calibration algorithm and 3D alignment algorithm embedded in the products, which can well meet the needs of the scenarios proposed by customers. For example: 2.5D products touch module binding, lamination process section automation assembly, wearable products lamination process section automation assembly, 3D curved products production assembly equipment lamination process automation assembly. At the same time, the product has a large range of precision flexibility to provide the most cost-effective solutions according to customer precision needs.

From the products exhibited at this exhibition, we can see that there are mainly horizontal and vertical highlights: horizontally, the variety of products exhibited at this exhibition exceeds that of any of our previous exhibitions, which is mainly attributed to the fact that the leadership of the company attaches great importance to market research, collection of user requirements and R&D and manufacturing implementation. The rich variety of products exhibited is also intended to give our customers a more comprehensive and in-depth understanding of Xinxiwang's products and the expansion and innovation of Xinxiwang in product technology in the past few years through this exhibition. For example, when the high-precision alignment system passed the evaluation of scientific and technological achievements at the beginning of this year, the alignment accuracy was 3μm, which was recognized as the leading level in China by the expert group, and now the alignment accuracy can reach ±1.5μm. In addition, all our products contain our own intellectual property protection, and the localization rate of our products has reached over 80%. In the context of accelerating the process of domestic substitution in the industrial field and gradually increasing the market share of local manufacturing, Xinxiwang's machine vision products provide a non-negligible role for industrial manufacturers to reduce costs and increase efficiency.

The first step is to continue to maintain and expand the competitiveness of its advantageous products in the industry, and make breakthroughs on the basis of the existing parameters of alignment, inspection products and other series products; the second step is to expand the product range oriented by user needs, and all the expanded products of Xinxiwang are based on user needs. This makes the company have strong mobility and sensitivity in product strategic planning, and also reduces the company's potential R&D risks and invalid capital costs.

Q: We believe that the future machine vision technology needs to overcome the following challenges: higher speed, combination with smart factories and Industry 4.0, shifting from 2D to 3D and multi-dimensional, detection of special materials, and special application scenarios. Do you have any deep experience or add anything to the above mentioned? What positive technical enhancements or innovations has your company made on the above mentioned technology trends?

A: From the current state of the machine vision industry, machine vision, with its own unique measurement and judgment technology, has already occupied a place in the field of industrial intelligence and gradually ranked among the key positions in the manufacturing industry. In the future, companies will focus on combining smart factories with intelligent production to increase the penetration of machine vision equipment in the manufacturing industry. Although the current 2D detection algorithm has reached a high level, but there are still more detection shortcomings, as machine vision applications more extensive detection, companies will continue to make breakthroughs in detection technology, and gradually complete the upgrade from 2D machine vision to 3D machine vision. In addition, machine vision technology due to the superiority of the technology is not limited to the traditional application scenarios in the past, the future will involve more special areas to improve the irreplaceability of the technology itself.

In this technology development trend, firstly, Xinxiwang absorbs more professional compound talents by vigorously investing in R&D; secondly, on the basis of in-depth analysis and accurate grasp of the market, it taps the contradiction between user needs and realistic and feasible technology; finally, it solves such contradiction through R&D to form independent products recognized by the market. For example, we found that although the 2D vision system can achieve pixel-level high-precision plane alignment, it is difficult to achieve accurate alignment assembly at the three-dimensional level because the 2D vision system cannot obtain the spatial coordinate information of the object, and for the realization of three-dimensional alignment assembly, it is usually necessary to reconstruct the three-dimensional model of the component based on the three-dimensional information of the component to be assembled, so as to determine the posture of the component in space to achieve alignment assembly. If we can achieve 3D positioning at the pixel accuracy level on the basis of 2D images, it will greatly improve 3D positioning accuracy and reduce implementation costs.

Q: As the market of machine vision industry becomes more and more mature, more and more companies are transforming from product suppliers to service providers, what do you think about this?

A: I think we should look at this issue in a dialectical way.

First of all, with the machine vision industry market is becoming more and more mature, the transformation of enterprises from product suppliers to service providers in a reasonable and orderly manner is an inevitable requirement of the market economy, enterprises through the previously accumulated technical experience to the transformation of machine vision comprehensive service providers, short-term cost reduction and efficiency for enterprises, long-term help to enhance user adhesion, and ultimately to enhance the overall competitiveness of enterprises.

But as the saying goes: too much is too little, and the desire for speed is not enough. From the perspective of the industry as a whole, if the vast majority of product suppliers are going to service providers transformation, not only will enhance the bargaining power of upstream product supply or even the formation of a monopoly, and ultimately the service provider profits eat very thin, a large number of transformation service providers may also form a vicious competition between enterprises, these situations will be detrimental to the overall development of the industry, too late, it is better not to turn.

From the point of view of the enterprise's own development stage, an enterprise without sales expansion, R & D technology accumulation and precipitation, the transformation of smart manufacturing alone to do service providers, the subsequent will be a series of problems such as lack of orders, technical support, supply chain risks. In this regard, enterprises should be down-to-earth and rationally assess their own situation before making a decision.

Q: From the perspective of the current industrial environment, in which segments of machine vision will usher in rapid development? What measures will your company take in response?

A: At present, China's machine vision industry is developing rapidly, with a compound growth rate of 21% from 2022 to 2025. According to China Machine Vision Industry Alliance, China's machine vision market size reached 18.1 billion yuan in 2021 and is expected to reach 39.3 billion yuan in 2025. According to the data analysis of GaoGong Industry Research, machine vision has been widely used in 3C electronics, semiconductor, automotive, lithium, food packaging and other fields in 2021, of which, 3C electronics industry is the largest downstream application of China's machine vision industry, accounting for 31.56%, followed by semiconductor, accounting for 10.22%, the third is automotive, accounting for 11.04%.

In view of the above segments, the R&D team of New Siveco has conducted in-depth research and model building on top of the common framework of vision inspection process of alignment fit and appearance defect detection, through the interpretation of different segmentation scenarios, with alignment fit accuracy, accuracy rate and algorithms applicable to different scenarios as the breakthrough point. We are now building our own library of algorithms to address and filter the best technology routes in various segments.

For example, 2D machine vision technology and 3D machine vision technology: 2D machine vision technology can provide results based on contrast features in grayscale or color images for missing/presence detection, discrete object analysis, pattern alignment, barcode and optical character recognition (OCR) and various 2D geometric analysis based on edge detection, fitted line taping, arcs, circles and their relationships (distance, angle); 3D machine vision technology can be used to provide depth measurement, and to provide a better understanding of the relationship between the two. Machine vision technology can be used to provide depth measurement information to ensure that objects move anywhere in the measurement volume while still ensuring accurate measurement results and achieving reduced system design and maintenance costs. Therefore, our company is combining deep learning with traditional machine vision algorithms, 2D machine vision technology and 3D machine vision technology, in order to play a good first move in the fast-growing segment.

Q: What is your overall impression of VisionChina2022 (Shenzhen)? What are your expectations for the future development of machine vision in China?

A: The VisionChina2022 (Shenzhen) exhibition, both from the preliminary publicity and the overall layout are very positive, in a more intuitive and vivid way to understand the needs of customers, while as a technical exchange platform carrier between enterprises in the same industry, to understand the industry development trend, which will help the development of the company.

My expectations for the future development of the machine vision field in China are mainly twofold.

First, in terms of the current Chinese machine vision field, artificial intelligence algorithms do not have an absolute advantage over classical machine vision algorithms. In terms of industrial inspection accuracy and precision alone, the existing mature traditional vision algorithms are fully capable of performing. But through the national transformation and upgrading of the manufacturing industry to intelligent manufacturing vigorously support, it can be seen that the machine vision industry in the deep learning algorithms have a very broad market development space. Artificial intelligence defect detection has begun to replace the traditional algorithm detection in specific application scenarios, through a large number of training in the future from the detection accuracy and precision of the two dimensions over the traditional algorithm is very likely;.

On the other hand, machine vision as China's industrial manufacturing auxiliary industry, the service object is always manufacturing, and now the manufacturing industry is facing two major changes, one is the technology upgrade, intelligent manufacturing gives the future production line structure rich imagination; ultra-high-speed ring production line on the visual inspection accuracy requirements are not so strict but the detection frequency requirements are very high, flexible mold may lead to template matching detection failure, etc.. Secondly, energy saving and environmental protection, imagine in the era of carbon neutral, the future more and more zero carbon factories, zero carbon industrial park production line structure in the technology will be supported by what huge changes. These changes will bring what kind of revolution to our machine vision industry, which is worth every industry colleagues look forward to and think about.