From March 15th to March 17th, 2016 Shanghai International Machine Vision Exhibition & Seminar on Machine Vision Technology and Industrial Application (Vision China) was held in Hall W2 of Shanghai New International Expo Center. More than 150 well-known enterprises in the machine Vision industry participated in the exhibition, and more than 20 forums brought a feast of machine Vision to the participants.

This year is the second time for Cognex to participate in the Vision China(Shanghai) exhibition. We were honored to be invited by the organizer of the exhibition to answer questions about the relationship between machine Vision and Industry 4.0. Konnex view that: "Industry 4.0 is intelligent manufacturing, and the premise of realizing intelligence is that all resources in the factory are" linked "to each other, the future of industry 4.0" linked "is intelligent induction, perception. You can See, Hear and Feel like a human being. Machine vision is the key to assist Industry 4.0 with sensory sensing capabilities. Cognex is derived from Cognition Expert. As the world leader in machine vision field, Cognex has carried out continuous and in-depth research on Industry 4.0 and developed many advanced products. Cognex is ready to help achieve Made in China 2025." When it comes to the development trend of the machine vision application market, Contech gives a very positive judgment that the advanced technology of machine vision has a very good development trend, which will help realize the Made in China 2025 strategic planning and promote the supply-side reform.

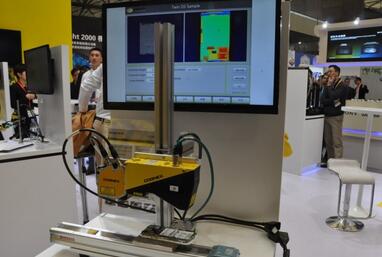

In this exhibition, Cognex focused on the display of Aignplus visual guidance of high-precision alignment solutions, 3D displacement sensor-visual detection system, and just launched the new products In Sight 2000 vision sensor, Dataman reader and other major products and solutions, Represents the most advanced technology level in the field of machine vision.

AlignPlus has three characteristics: one is fast automatic calibration, to achieve high precision alignment. With self-patented automatic calibration function, it can help customers quickly and automatically calibrate, correct lens distortion, perspective distortion, compensate platform error, support closed-loop alignment, and achieve a more precise accuracy than 5um in the display panel manufacturing process (such as fitting). Second, it is easy to develop and maintain. The template-based visual software designed based on Designer graphical development environment can directly use mature standard templates to quickly complete visual development tasks; The software interface design is friendly, and the system is easy to operate and maintain after deployment. The third is to support customers to choose a variety of flexible hardware configuration, can choose XY? Or UVW motion platform, single platform or dual platform, you can choose a single camera or up to 16 cameras, you can choose industrial computer with vision software card or professional vision controller and so on. AlignPlus is suitable for application in the display panel industry, including the bonding and binding of the display screen, glass printing of the cover plate and other production processes.

3D displacement sensor-vision detection system has three characteristics: First, the 3D camera and VC5 vision controller, to provide a complete 2D and 3D vision detection functions. The second is to achieve micron-level measurement accuracy in the Z axis (depth, height) direction. It has a unique field calibration technology, without the need to worry about the accuracy caused by mechanical installation or motion errors. Third, the product hardware structure design is compact, in which the DS925B size is 85mm x 96mm x 33mm. The graphical development environment of Designer software, with a single quick scan, can output a complete 3D image, supporting rapid prototyping and project evaluation. Because of the above three characteristics, 3D displacement senors-visual detection system is very suitable for segment difference measurement, flatness, height of parts, thickness of rubber line, tire character, instrument measurement and other applications in the electronics, automotive, pharmaceutical and other industries.

A new vision sensor, the IN-Sight 2000, was unveiled for the first time at the show and also attracted a lot of attention. It has three characteristics: one is powerful, equipped with mature in-sight visual tools and on-site replacement of lighting and optical devices. It uses a 1/3 inch CMOS imager, 640*480 resolution and supports image amplification mode for higher resolution, has a acquisition speed of 40 frames per second, and supports a variety of communication protocols. Includes Ethernet, Ethernet /IP, ROFINET, SLMP, SLMP Scanner, TCP/IP, UDP, FTP, RS-232 Text; The second is simple to use, with friendly interface of EasyBuilder and Insight Explorer software interface, intelligent guide users to easily complete parameter setting and visual detection tasks. Three is cost-effective, especially suitable for customers to "exist/missing" and other qualified/unqualified determination and detection of the application. Suitable for automobile, consumer electronics, food and beverage, pharmaceutical and other industries in the production process of anti-misloading, with/without testing and other applications. The modular design of the hardware and the ease of operation and setup of the software set a new industry benchmark for the "flexibility, ease of use, and value to customers" of the vision sensor.

The Dataman Reader has three prominent features and advantages: One is the extremely high read rate, because we have advanced software algorithms, 1DMAX ®, 2DMAX ®, Hotbars® II, PowerGrid™, can read all types of QR code, even including strong perspective distortion, fuzzy code, low contrast, quiet area interference, damage; Easy-to-use tuning and trigger buttons; Second, the extremely high reading speed and extremely flexible hardware configuration is optional; The third is excellent ease of use. Take the new Dataman 150/260 as an example. The tuning and trigger buttons can set up the application without the need for a PC or HMI. Once the reader is installed, just press the button. Whether it is a tag code or a direct part identification code, the tuning algorithm can learn to adapt the code and automatically adjust the light path and lighting to produce the best image for the application. It's even easy to get the Reader app from Google Play or the iTunes App Store on your phone, view images in real time, adjust configuration Settings and share Settings between multiple readers, save and send images, and more. Get a head start on Industry 4.0 by troubleshooting and checking read rates from anywhere in the factory or distribution center via mobile phone, anytime, anywhere.