Q: What products, technologies and solutions will your company bring to VisionChina2022 (Shenzhen)?

A: We have brought a total of four products to the exhibition in two exhibition areas.

The first is the industrial visual intelligence platform, which is mainly training and low code, and can quickly realize AI development, marking, training, testing and deployment of the whole process closed-loop. In the machine vision intelligent equipment exhibition area, we have prepared three products: one is the surface detection equipment for ceramic tiles, one is the surface intelligent defect detection equipment for flexible lithium batteries, and one is the defect detection equipment for PCB (intelligent online pcb-AOI). These three devices are actually developed and manufactured by the partners of the Dharma Institute, in which the core AI algorithm capability of the Dharma Institute is used.

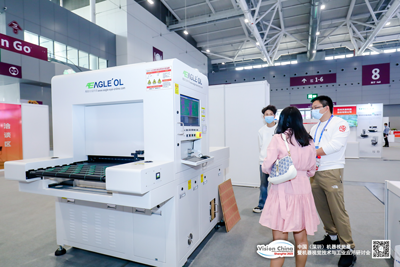

The surface inspection equipment for ceramic tiles developed by Bosch Intelligent Control can conduct real-time quality inspection, greatly reduce the missed and wrong inspection of ceramic tiles, improve product quality, improve quality inspection efficiency, and provide defect back inspection and intelligent statistical report functions to facilitate customers' quality management and product analysis; The intelligent defect detection equipment for the surface of the soft package lithium battery also launched by the company collects the multi spectral images of multiple surfaces of the battery through the dynamic continuous collection of multiple stations, which is suitable for accurate detection of dozens of types of defects such as pits, scratches, aluminum leakage, pinholes, overflow, appearance glue, etc. on the soft package batteries packaged with black, silver and other aluminum plastic films; The defect detection equipment (intelligent online PCB-AOI) of PCB from Eagle Eye Technology makes full use of the advantages of machine vision in realizing non-contact detection, wide spectral response range, online real-time, long-term stable work, positioning, etc., and reserves a deep learning interface, which can solve more complex business scenarios with the support of deep learning. Our products and equipment are often highly related, and the AI capabilities used in the equipment are all produced by our micro industrial visual intelligence platform.

See the reason why the micro industrial visual intelligence platform can be selected into the "2021 Top 10 Machine Vision Innovative Products" is that our AI is not just a platform, but the attributes of the platform are just a core. In the innovative product exhibition area, in addition to the micro industrial visual intelligence platform developed by Alibaba, there is also a training platform developed in cooperation with partners. It can take deep learning as an operator to more completely serve the entire visual intelligence process, and it can also more easily realize visual intelligence capabilities including AI in various devices.

Q: See where the innovation points of micro industrial visual intelligence platform are mainly reflected? What are the characteristics of the equipment in the machine vision intelligent equipment exhibition area at the application level?

A: From the perspective of product characteristics, there are actually many AI platform friends. Everyone is similar in the main process, starting with tagging, data structure management, and ending with training and testing. Therefore, there is often no breakthrough in innovation in the main process. We may have a slight advantage in the ability of basic models. In addition to the main process, the largest part of AI application workload is annotation and data management. In this regard, we have some innovations: for example, the intelligent annotation made by automatic contour extraction can greatly improve the efficiency of the whole annotation. The label efficiency does not mean the label quality, but the label quality will directly determine the performance and related indicators of the subsequent model. For the evaluation of annotation quality, we also provide an intelligent algorithm - it can automatically see whether there are significantly different outliers on the annotation. These outliers may lead to the decline of the whole annotation quality, or cause confusion, thus affecting the following algorithm indicators. At present, I think that the innovation of AI training platform in the future may revolve around the key point of "data centric".

In addition, we have several special applications: one is a highly reflective surface like ceramic tiles. We used multi frame plus template comparison and multi graph joint training, which are some innovations for algorithm modules and training frameworks. On the highly reflective surface, we capture different images with different light sources to capture different types of defects. The training of neural network with multiple light sources and multiple images is more helpful to improve the ability to capture defects. Secondly, as far as neural networks are concerned, 2D and 3D are the same as human eyes. 3D itself is a concept, and the real image of the human eye is two-dimensional. When using image related neural networks for reasoning or training, we will two-dimensional 3D images. Of course, based on big data, 3D itself can also deeply learn location information, but that is not entirely in the field of vision, but in the field of data intelligence.

Q: As the machine vision market continues to mature, more and more enterprises begin to transform from product oriented enterprises to service oriented enterprises. What do you think about this?

A: We very much hope to promote the commercialization of services, because the service cost is a heavy burden for all participants in the industrial chain. In the past, customers would pay for products, but how would they pay for services, and who would bear the cost of services? This is the bottleneck of commercialization that restricts the better development of the entire industry.

But now, I think there may be some changes: because customers prefer to obtain continuously available and more efficient products. With the application of AI, the service itself has also made a transformation from the maintenance of equipment, and customers may more easily accept the value brought by the service itself. I think there is a need for higher value presentation, which is also a service. Why are customers more willing to pay for the services of management software today, and why are they more inclined to pay for the operation and maintenance of the equipment itself? Because our value has not been promoted to the higher management dimension, we need to integrate the lowest level structured data with the intelligent decision-making data of the management dimension. If there is such application integration, I think customers are more willing to pay for the value.

The second point I think is that service tools and service resources can guarantee the quality of service and control the cost of service. Today, we have many tools, such as the industrial visual intelligence platform. Such tools are too general in specific service scenarios, and their effectiveness may be low. At the same time, they rely too much on the service provider, that is, human capabilities, which makes the quality of the service itself non standardized. For customers, your service value and efficiency may also be non-standard. For non-standard products, the willingness and ability to pay is certainly low. Therefore, I believe that in the future, not only AI, but also traditional vision, and even IT solutions for equipment operation and maintenance tools need to be further evolved. With the evolution of these tools, the steps, processes, and quality of the service itself can be more standardized and consistent, and customers' willingness to pay will be stronger.

Q: Which segments of machine vision are you optimistic about? What are the expectations for the development of the domestic machine vision industry?

A: Now we are mainly focusing on several major directions: lithium battery, 3C, and semiconductor. 3C covers a lot of subdivided fields. We still hope to have more cases on 3C products, because its relative complexity is higher. In terms of concept, it has many very high requirements on safety, such as welds. Like sealing machine, we will continue to invest in these fields, including its electric core and pole piece. In addition, there are crystal components of semiconductors. We believe that semiconductors will be greatly expanded in the future. In addition, the substitution process of many equipment from import to domestic will also generate a lot of business opportunities, and there is also a stronger demand for equipment.

"Future development of machine vision industry" is also a long-term topic in the industry. I think standardization should be the first. In the process of establishing standards, the participation of the application companies is crucial. The second is the application of new technologies. For example, 3D is now faster and faster, and its overall imaging efficiency is constantly improved. It can transmit faster for algorithms and applications.

Q: What's your overall impression of this VisionChina (Shenzhen) exhibition?

A: First of all, I think it is very difficult to hold the exhibition in such an environment. We once thought that the exhibition would probably be cancelled or postponed due to the current epidemic situation in Shenzhen. From the perspective of the exhibition itself, the participants are more and more abundant. I have seen some familiar enterprises whose booths and products were relatively simple a few years ago. This time, the exhibition content has been very rich, and it can be predicted that their business volume has grown greatly. From the perspective of application, we hope that more application parties can participate in the future, such as semiconductor wafer manufacturers, PCB manufacturers, etc., so as to attract more demand parties to enter and better drive the diversity of our exhibition.