Vision Dialogue with Senior Executive

What will be the growth of machine vision applications in the Chinese market and the global end product sector in the next few years? Under the background of Made in China 2025, how will the enterprise's development strategy be adjusted? What technology convergence will the company focus on in the future?

China (Shanghai) Machine Vision Expo 2021 launched the "Vision Dialogue Executives", invited exhibitors executives to have a dialogue. What do executives think of the above questions? Let's listen to the following steps.

In the first 3D

Character introduction: Yang Yang

First Pro 3D 3D Digital Division Executive General Manager

Q: Under the background of Made in China 2025, equipment manufacturing is the core and pillar of the manufacturing industry. What is your company's development plan and strategy in 2021? How to better apply the company's products to the equipment manufacturing industry?

A: The development level of equipment manufacturing industry is an important reflection of a country's comprehensive national strength. It is a fact that China's equipment manufacturing industry is now "big but not strong", and some core technologies and key technologies have been "stuck" by foreign brands for a long time. Of course, our local enterprises are also constantly working hard to overcome this shortcoming and change this situation.

With the rise of machine vision technology, it is playing a more and more important role in the equipment manufacturing industry. Its advantages of high-speed access to accurate data can help the measurement, detection and data model restoration in the process of equipment manufacturing. Advance 3D is also digging in this field.

Founded in 2004, we are engaged in 3D digitization and 3D printing technology for more than 10 years. The company's brand "Tianyuan 3D" is more focused on providing high-precision 3D vision detection solutions. For a long time, we have attached great importance to independent research and development, and invested more than 120 million yuan in hardware and software development every year. For example, our company released the self-developed Einsense Q 3D digital testing software last year, which greatly improved the efficiency of automatic testing and alleviated the problem that some domestic enterprises were "stuck" by foreign technologies. In 2021, our company will still increase its independent research and development efforts, and cooperate with high-end manufacturing enterprises in different industries to meet the needs of specific industries and provide more solutions to improve the quality of manufacturing in China.

Q: In the next two to three years, which end product areas do you think will see growth or new market demand for machine vision applications in China and globally? How will your company deal with it?

A: From the perspective of our attention to the industry, 2D vision technology is more popular at present, but more and more users have gradually improved the requirements for measurement accuracy, and the measured objects are becoming more and more complex. The limitations of 2D vision technology will not be able to meet the requirements of customers. With the continuous improvement of 3D vision technology in precision, efficiency and automation, coupled with the empowerment of artificial intelligence and 5G in the future, the development of data information from 2D to 3D will be accelerated. 3D data will also be more comprehensive, more accurate and more reliable, which may generate new market demand and rapid growth. According to the current observation, the application of machine vision in measurement and detection, reverse design, data archiving, redesign, 3D printing and other fields will gradually deepen.

Tianyuan 3D, the brand of Xianlin 3D, focuses on 3D visual inspection technology, and has invested in 3D visual software and hardware technology for many years. As mentioned above, we will also cooperate with more manufacturing enterprises to accelerate the application and development of 3D visual inspection technology and market development.

Q: Cross-boundary cooperation and technology integration is the current trend and opportunity of the entire machine vision industry. With the current innovative technologies, such as edge computing, artificial intelligence, deep learning, embedded vision, 5G+, etc., which innovative technologies will your company focus on in the future?

A: 3D digitization and 3D visual detection technology can quickly and accurately collect 3D data of real objects. The amount of data is much larger than traditional 2D data, and complex data processing usually requires manual intervention. We need to further break through the bottleneck of efficient transmission and calculation of large amounts of data, and realize cloud computing and processing. Through the improvement of software algorithms, we can reduce or do not need human intervention, meet the efficient and fast tempo of the production line, and realize high precision, high efficiency and automatic online detection. Therefore, the company must further strengthen the technical research of 3D digital algorithm and improve the degree of software and hardware integration. The improvement of these technologies must be inseparable from the integration of edge computing, artificial intelligence, deep learning, embedded vision, 5G+ and other cutting-edge technologies, so as to meet more and higher application needs in the field of industrialization.

Q: Visionchina2021 (Shanghai) Exhibition, what latest technologies and products will your company bring to the exhibition? What are the highlights of the main product?

A: At this exhibition, we brought the new Multi-OptimScan structured light multi-machine linkage automatic 3D detection system: It is equipped with a number of high-precision detection equipment, which can be efficiently interconnected through the self-developed control system. It adopts the "no mark" tracking algorithm and high-speed big data transmission and processing module, and integrates the self-developed 3D digital detection software, which can realize the "one-click" completion of multi-angle scanning and real-time online detection. Create a high precision, high efficiency, automatic pipeline batch detection method. At the same time, the system is a customized solution, no need to manually repeat scanning, no need to move the detection equipment and samples, can break through the traditional 3D visual detection is limited by the size of the workpiece and the site, can be used in aerospace, shipbuilding, It plays a role in the detection of super-large workpieces in heavy industrial fields such as wind power generation and the scanning and detection of complete data of small size samples in 3C fields.

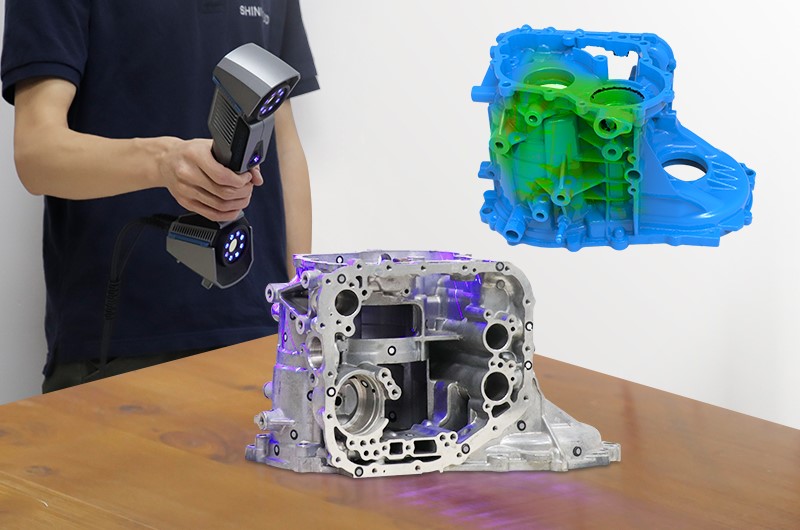

At the same time, we have also brought some portable 3D scanning products, such as OKIO 9M metering 3D scanner, Freescan UE blue laser handheld 3D scanner, Einscan H dual light source color handheld 3D scanner, Einscan Pro 2X 2020 handheld 3D scanner, These products can be used for high-precision detection, 3D data acquisition and other applications, and can serve various fields such as high-end manufacturing, cultural relic sculpture, medical care, cultural creativity and so on.

Freescan UE blue laser hand-held 3D scanner

Einscan H dual light source color handheld 3D scanner

----- Finish this article