On March 19th, the Machine Vision Industry Alliance (CMVU) successfully held the award ceremony for innovative machine vision products in Shanghai New International Expo Center. "Machine Vision Innovative Product Award" is one of the important activities of the Alliance. Its purpose is to encourage and accelerate the industry enterprises to improve the ability of independent innovation, and constantly improve the influence, competitiveness and brand power of enterprises.

CMVU President Pan Jin said, "The selection of machine vision innovation products is to showcase the latest development achievements of China's machine vision industry, to show the world the development achievements of China's machine vision technology, to encourage the morale of the industry, to gather the spirit of the industry, and to make a greater contribution to the development of the country. The selection process of the 2020 Machine Vision Innovative Product Award has gone through solicitation, free declaration, formal review, letter evaluation and final evaluation organized in the form of defense, resulting in the 2020 Machine Vision Innovative Product Award.

This innovative product award eventually selected and three gold medal, a prize LingYunGuang technology co., LTD. Yi, vice President of union vice President and vice-president of the union of shenzhen visual dragon technology co., LTD., general manager of sway, league east China area, deputy secretary general, Shanghai Bert Lu Xingzhong came to power, the general manager of our company for winning enterprise awards.

Zhongke Huiyuan Vision Technology (Luoyang) Co., Ltd. won the "Special Prize" of 2020 Machine Vision Innovative Products

Testing equipment for the appearance defect of glass cover plate

Zhongke Huiyuan glass cover surface defect detection equipment, is a glass cover surface micron level defect detection equipment. Focus on the application of machine vision technology in the industrial field, in the industrial appearance inspection, precision micro assembly, high-speed vision technology and other cutting-edge technology has many years of experience, and continue to invest in research and development, to solve the core parts rely on foreign imports of "jam neck" problem. The inspection equipment for glass cover defects broke through the monopoly of Germany and fully realized independent research and development. The detection accuracy reached 10 microns, and all the inspection indexes exceeded the German standard. After two years of market verification, it became the first enterprise in China to realize the industrialization and mass production of the inspection equipment for glass cover defects. Solve the problem of China's industrial appearance inspection, and achieve a magnitude improvement in efficiency and performance.

Yimu Technology won the "Gold Award" of 2020 Machine Vision Innovative Products

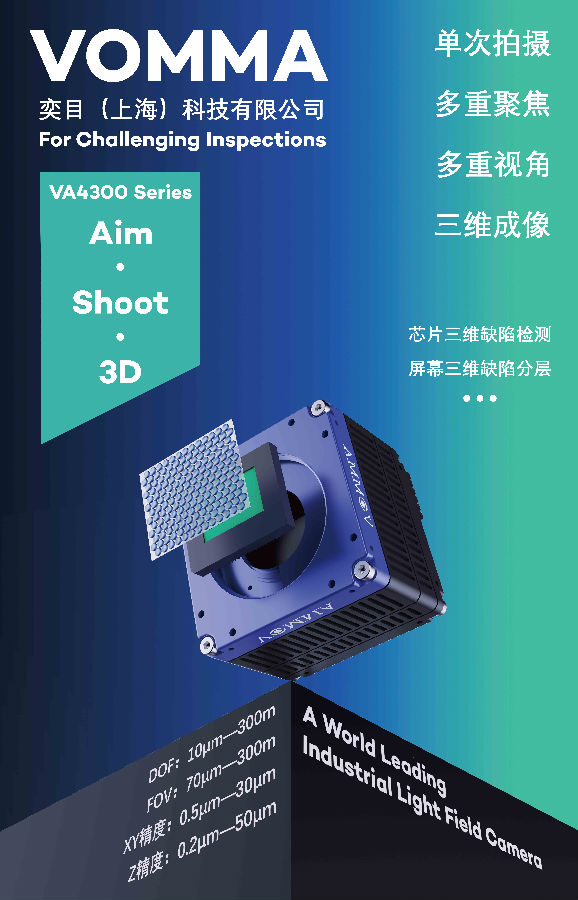

3D light field camera

The VOMMA light field camera uses a unique combination of ultra-high resolution microlens and CMOS to achieve the imaging effect of multiple traditional cameras taking surround shots, namely "single camera, single shot, multiple focusing, multiple viewing angles, three-dimensional measurement and modeling". Yimu Technology Co., Ltd. is the only optical field 3D imaging technology company in China that fully master all the core technologies of optical field camera optical design, packaging and manufacturing, three-dimensional rendering of optical field image, and precise and rapid three-dimensional detection. It is also the first company in the world that applies optical field camera to three-dimensional defect detection of chip and three-dimensional defect layering of screen.

Baidu Intelligent Cloud Won the "Gold Award" for 2020 Machine Vision Innovation Product

Industrial visual intelligence platform

Baidu Intelligent Cloud Industrial Visual Intelligence Platform is an industrial-oriented visual AI application platform, which integrates Baidu's self-developed AI algorithms, models and all kinds of hardware computing power as the core. Provide model training, model optimization and model prediction services for the whole process of "0" code. It is equipped with AI tools such as data alignment, model training, model testing and model distribution, model management and project management to help industrial production and manufacturing customers achieve cost reduction and efficiency increase through AI applications in industrial visual scenarios such as quality inspection and inspection.

Xintu Optoelectronics won the "Gold Award" of 2020 Machine Vision Innovative Products

Scientific grade CMOS refrigeration camera Dhyana95 V2

Dhyana 95V2 is the second generation of backlighting science-grade CMOS refrigeration camera launched by Xintu. It has the advantages of ultra-high signal-to-noise ratio and high dynamic imaging. Xin figure after five years of independent research and development, in the readout circuit noise control, noise pixels algorithm processing and sealed refrigeration core technology to achieve a comprehensive breakthrough, makes Dhyana95 V2 imaging performance fully promoted, reached the international advanced level, and can provide cutting-edge scientific research and core components localization of target with more comprehensive technical support and guarantee reliability.