The IntelliSense solution is part of the long-term strategy of Motorola's Motorola based chip company, which went public on Nasdaq in 2000. Today, we are joined by Sammy Yi, Vice President of Global Marketing and Applications Engineering, ASM Intelligent Sensing, to hear how ASM sees the potential for the industry after the outbreak and how the company plans to integrate new technologies into its future strategy.

Yi Jihui Vice President of Global Marketing and Applications Engineering

Sammy shared his thoughts on the development trend of machine vision industry after the epidemic. He said that at present, the world attaches great importance to industrial and manufacturing industrial upgrading, such as Industry 4.0 and other plans, which point out the direction for industrial development. To achieve this, machine vision plays an indispensable role. We have seen that machine vision plays an important role in the prevention and control of the epidemic, such as the automatic production of masks and other protective materials, intelligent logistics sorting, face screening and recognition, etc. As the name suggests, machine vision technology for the machine to install beyond the vision of the eyes and brain, so that the machine in the automation of efficient operation technology, can acquire images in real time, perceive the target. This provides more possibilities for industrial manufacturing, such as online quality inspection, guided robot precise positioning, full cycle traceability and so on. The factory of the future must be highly intelligent. And machine vision technology will be integrated into all aspects of the manufacturing process. ASM Semiconductor provides a full range of image sensor lineup and technical support to facilitate the development of the industry.

XGS family full range of products and mature applications will be presented in Shanghai exhibition

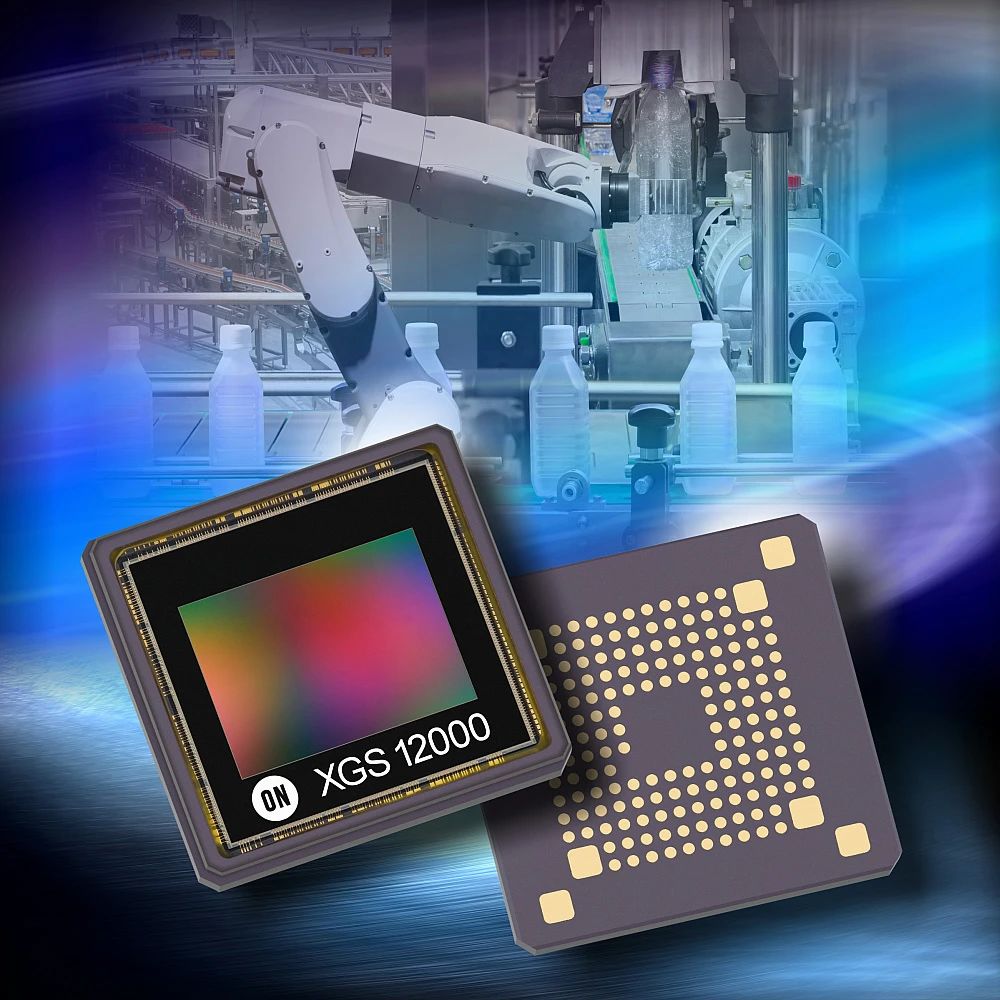

Vision China is a very influential exhibition in the industry, so we chose to present the flagship solution of ASM Semiconductor here -- the full range of XGS products. XGS is based on ASM's latest 3.2 micron Pixel, global exposure CMOS image sensor technology. - Sammy Yi

Compared to existing products on the market, the XGS has a full range of resolution options, from 2MP to 45MP, excellent image quality, high frame rate, low power consumption, wide operating temperature, and a very cost-effective advantage. Another XGS is belong to the X - Class image sensor platform, the platform through the same CMOS image sensor framework to support multiple pixel structure, flexible camera design new dimension, it makes a single resolution camera design can support a variety of products, the camera manufacturers can make full use of existing parts inventory and speed up the new camera design available time. This generation of products will overturn the current market competition pattern, providing users with a very attractive choice.

XGS 12000 is a member of the XGS family

According to Sammy, mainstream industry users have already chosen our solution. In fact, in VisionChina (Shanghai) exhibition, you can see that some end customers use our XGS5000's high frame rate feature to conduct high-speed production line inspection, our XGS12000's low power consumption and low cost advantage to serve as logistics code scanning equipment, and our XGS45000's low noise and high resolution advantage to conduct LCD screen inspection. In addition to machine vision, our product solutions are also suitable for other high-performance image sensor applications, such as intelligent transportation, 3D imaging, unmanned aerial vehicles, scientific research, etc.

AI+5G+ machine vision = revolutionary change

Talking about the new blood that the latest AI and 5G technologies have injected into the machine vision industry, Sammy told us his understanding. "The development and popularization of artificial intelligence (AI) and 5G technology will bring revolutionary changes," he said. AI greatly improves the capabilities of traditional machine vision technologies. For example, in textile defect detection, it is difficult for traditional algorithms to clearly extract defects from complex patterns, but AI can do this. In addition to optical character recognition (OCR), AI is very good. In this year's novel coronavirus epidemic period, AI is a great display of skill, mask production because of the introduction of AI algorithm, achieved high precision determination, cutting, automatic detection, greatly improved production efficiency; All kinds of efficient management and convenience services brought by artificial intelligence, such as health code, AI doctor, medicine and food delivery robot, make the non-contact operation mode more efficient and reliable. The ASM chip can be connected to the current mainstream AI platform, and we provide a ready-made reference design, which greatly reduces the development difficulty."

5G networks provide convenient, high-speed, high-bandwidth, low-latency, high-reliability data transmission channels, which makes sense for machine vision. Usually, the amount of data of the image sensor is relatively large. For example, we have a 12M image sensor, and the amount of data of a frame is 144MB (12bit/pixel). If there is no high-speed, high reliability network, such data volume can only be processed directly at the terminal, which limits the information processing and interaction ability. With the support of 5G network, data can be sent to the cloud and more complex operations can be realized and the results can be returned in real time. For example, during the anti-epidemic period, the combination of 5G and vision enabled people to act as a "cloud supervisor" for once.

We also asked Sammy for his thoughts on the innovative fusion of machine vision and multiple technologies. "We think AI and embedded applications will be the next big direction for machine vision," Sammy shared. In the past few years, AI has shown great power and has been integrated into everyday life. Combining AI will also revolutionize machine vision. Embedded applications are another area of concern. At present, most of the machine vision applications we see are discrete, which provides enough flexibility. But as embedded processor performance improves and industry standards improve, we expect there will be a lot of room for embedded machine vision applications in the future."

As a leading supplier of image sensors, ASM Semiconductor is committed to providing better solutions for our customers. CMOS image sensors are divided into global exposure and curtain exposure two categories. Both products have their own advantages, and ASM will continue its research and development on these two products. In order to improve the sensitivity, BSI (backlit) technology, as opposed to FSI (forward-lit), has also been introduced into the image sensor. We believe that future image sensors will still pursue high resolution, high picture quality and low cost. This is also the goal of ASM semiconductor image sensor constantly innovating.