The first 3D line spectral confocal sensor developed by Entropy Intelligence Technology in China is mainly used to solve the problems of micro-nano 3D detection in the manufacturing process. Today, Entropy Intelligence Technology will bring you the application of 3D process detection to share, unlock the veil of 3D line spectral confocal sensing technology.

When you choose Entropy's 3D line spectral confocal sensor, you will have the key to solve the pain points of 3D detection in the current precision manufacturing process:

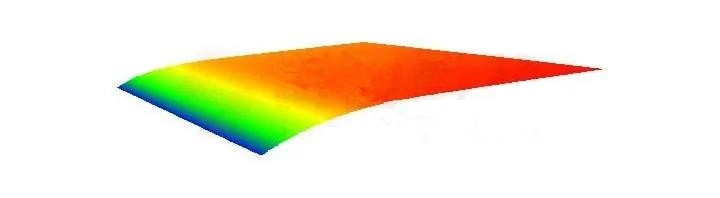

01- Mobile phone curved glass edge detection

The 3D line spectral confocal sensor has a maximum Angle compatibility of +/-25 degrees under the mirror. It can scan, measure and detect the contour of curved glass screens in mobile phones and tablets. It is very suitable for quality inspection of 2.5D and 3D glass displays.

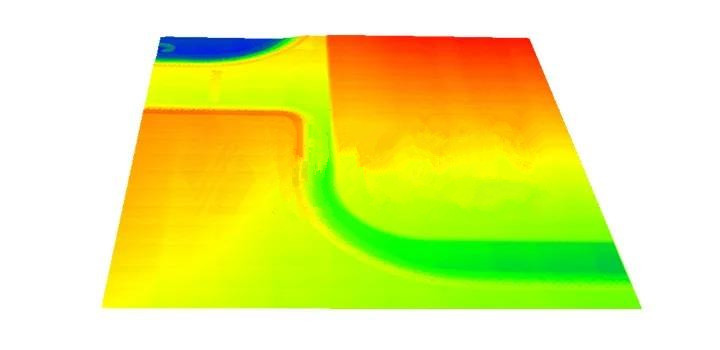

02- Precision mechanical structural parts testing

The 3D line spectral confocal sensor quickly measures part size, orientation, step height, clearance and surface difference, material thickness, and material surface characteristics (such as roughness and flatness). The 3D line spectral confocal sensor can also be used to detect the welding and bonding quality of micro-components such as PCB.

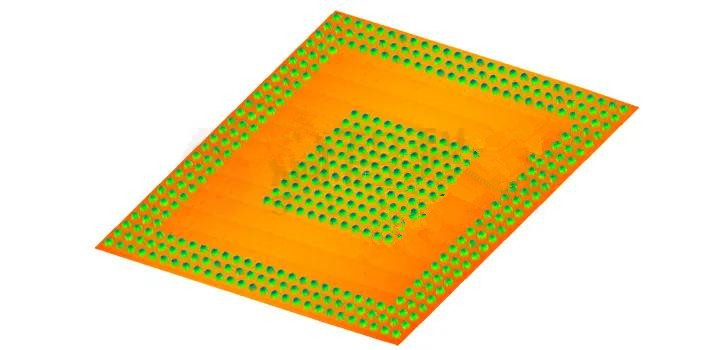

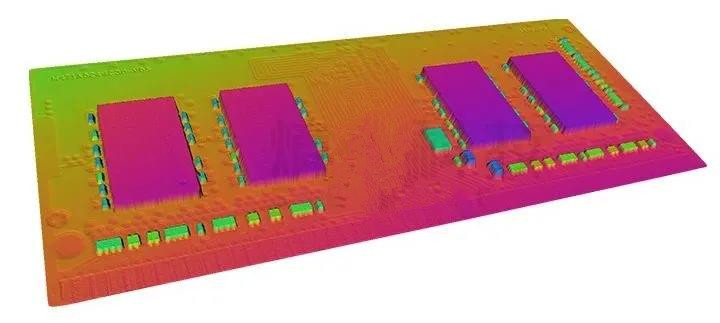

03- Chip packaging and testing

The 3D line spectral confocal sensor is very suitable for the detection of precision devices. One of the key applications is to detect whether the chip has design defects or physical defects caused by the manufacturing process.

Its ultra-high precision optical probe can be used to measure the height of the tin ball, the coplanar property of the tin ball, identify defects such as missing tin ball, offset, short joint, scratch, etc., and even measure the defect size at the submicron level.

04- Printing, testing of flexible electronic products

3D line spectral confocal sensors can be used in different stages of the manufacturing of printed electronic products. In the detection stage, the measurement of surface roughness plays a crucial role.

3 d confocal sensor detects the line spectrum all substrate materials, whether it is glossy, smooth or transparent (such as glass or polyester film), in addition, can identify the different defects, such as coating transparent carrying base material layer, scratches or impurities, such as structure of printing height and width of the steps of measurement, and quickly provide accurate 3 d topography imaging.

05- Medical applications

The 3D line spectral confocal sensor can scan for depth and shape of embossed and concave 3D patterns, for surface roughness and texture of extruded parts and mesh products, and for burr heights of precision embossed and micromachined medical parts.